PassivHaus Foundation Systems and Details

This article is the first in a series discussing how integrating Passivhaus ‘fabric first’ principles vastly improves the energy performance and quality of our buildings. Focusing on foundation design, the article highlights the three broad design strategies employed to optimise the thermal performance of the building.

This article is the first in a series discussing how integrating Passivhaus ‘fabric first’ principles vastly improves the energy performance and quality of our buildings. Focusing on foundation design, the article highlights the three broad design strategies employed to optimise the thermal performance of the building.

Context

As energy performance goals begin to rise, the potential for heat loss through the base of buildings has come in to sharp focus. Concrete basement walls, stem walls and slab edges can no longer be left exposed to winter air or frozen soil near the surface compounding thermal bridging, causing significant condensation and mould growth at key interfaces. Infiltration of cold air up through suspended floors has also been identified as a problem.

In answering such design challenges, designers proposed insulating the building perimeter down to a sufficient depth that the temperature differential between the soil and the foundation system was no longer considered a problem. Alternatively, insulation could be extended out horizontally from the building perimeter just below grade level. This protects the soil mass directly under the building perimeter from heat loss to the surface. Combination of these techniques is still in use today.

To meet Passivhaus standards in harsh climates such as those experienced in central and northern Europe, it is necessary to completely isolate the foundation system from thermal contact with the soil. In addition, perimeter drainage systems are required to reduce fluid pressure against such foundation systems as well as protecting the integrity of embedded barriers and materials within the system from soil that would otherwise be saturated with water.

Design Strategy

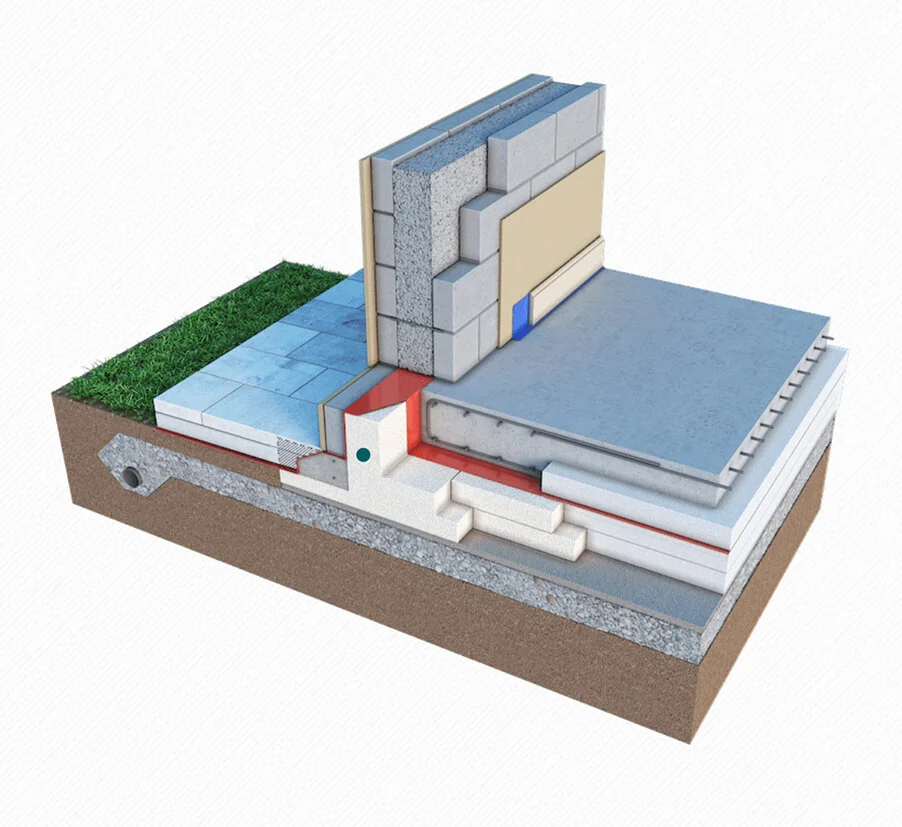

The core design challenge is to maintain thermal isolation between the structure and grade whilst transferring loads from the building via walls and columns to the foundation. The most straight forward approach is to surround the entire foundation in insulating material. This approach allows the mass of the foundation to hold the building down assisting detailing with all connections to the slab within the thermal envelope. It also has the added benefit of the slab acting as a thermal store for the building, enabling internal temperatures to be regulated more easily. Design challenges present themselves at interfaces with door openings and external landscaping, but these can be easily resolved via simple flashings and appropriate detailing to protect the integrity of the exposed insulation at the slab edge. There are numerous systems like this on the market presently from suppliers such as Kore Insulation and Isoquick.

Strategy 01

Insulated Raft Slab Foundation

A second strategy available for consideration is more of a hybrid of traditional strip foundations and the insulated slab outlined above. In this strategy, a conventional strip foundation, common in the UK, is installed with insulation extending down both sides of the sleeper wall (whether cast concrete or concrete block on a footing). This does not eliminate thermal conductivity through the base of the footing, but it does reduce thermal losses at the key interface with the ground floor. This option is popular as it is familiar with traditional foundation practices and can reduce concrete quantities. However, interfaces with other systems such as membranes and fixings are more complicated and difficult to control.

Strategy 02

Insulated Strip Foundation + Ground Slab

Where large amounts of concrete are considered undesirable or not possible for logistical or financial reasons, suspended timber ground floors with a ventilated air space below to control moisture from the ground are still possible to meet Passivhaus standards. With similar design challenges presented by the hybrid solution outlined above, care should also be given to maintaining integrity of the membrane and perimeter insulation at the interface with the required ventilation slots to promote airflow to the subfloor. This adds construction complexity, but if executed well, can provide a robust lightweight ground floor construction that performs well. Care should also be taken to ensure infiltration of cold air from the subfloor is eradicated through the inclusion of an airtight layer of appropriate board or membrane.

Strategy 03

Suspended Timber Floor

The three broad strategies outlined above if executed correctly, will provide a sound thermal bridge free foundation from which to realise your Passivhaus building. It is important to understand that the foundation is the first area where the thermal integrity and, by extension energy use, of the building is challenged. It is vitally important that clear dialogue of the building's energy strategy is communicated to the design team, in particular, the Structural Engineer and Architect, to ensure that all the hard work undertaken in the design and performance of the Superstructure is not lost at the key interface with the ground.

If you have found the above article useful and would like to understand more about the Passivhaus Standard, we would encourage you to read the other articles in our blog available at www.novo-design.co.uk/blog. Alternatively you can join our mailing list below.