Using PassivHaus to get to Net Zero Carbon

Designing to the Passivhaus standard can at times seem quite daunting and intimidating. Understanding the basic principles of the strategy is key, to ensure that you can develop your design to meet the standard without being succumbing to abortive work. This article outlines 10 broad design strategies to follow that will enable you to create a solid foundation from which your design can be developed, increasing your chances of meeting the required Passivhaus Standard.

The UK’s 2030 and 2050 Climate Change targets now look unlikely to be achieved with predictions showing that Buildings emissions will not reduce significantly given current use patterns and trajectories. To combat this, Scotland has indicated its intent to move towards a Zero Carbon building standard for all new buildings, using the Building Regulations as the primary mechanism. But what is a Zero Carbon building? In this article we explore this definition and present the Passivhaus Standard as a viable strategy in helping us achieve net zero carbon.

Embodied Carbon or Operational Carbon

The total carbon emissions of a building are made up of two types. Embodied Carbon describes the carbon emissions inherent in the creation of our construction materials. Operational Carbon, describes the carbon emissions generated in the use of our buildings through heating/ cooling, hot water, power and light. Our understanding of and ability to accurately calculate Embodied Carbon, whilst improving, is highly complex. Furthermore, the relationship between trading more Embodied Carbon to reduce Operational Carbon (for example, more insulation to reduce heating demand) is not yet fully understood or well established empirically. What is undeniable, is that we continue to build homes that are inefficient in operation, and unless this is addressed, high levels of Operational Carbon will continue to erode our ability to meet our Climate Change targets.

Credit: UKGBC

Carbon or Energy

In considering how best to reduce carbon emissions in the context of buildings, if we focus solely on carbon, it can be quite difficult to manage and propose strategies to reduce emissions. This is due to the complexities introduced by changing carbon factors associated with the energy mix of the grid over the life of the building. Furthermore, upgrading and replacement of different services over the life of the building can have significant carbon impacts that are difficult to estimate. It is far better to focus on the energy demand of the building. This is relatively consistent throughout the life of the building and is something that can be controlled and modelled at design stage. If the energy demand is minimised in the first place, then it follows that carbon emissions will be reduced. Design strategies such as Passivhaus, follow fabric first approaches to minimise the energy demand of the building. This energy use is focused on 4 principle areas; Heating & Cooling, Domestic Hot Water, Lighting and Auxiliary Electrical and finally, Appliances. To achieve net zero carbon emissions we need to offset actual energy use with energy derived from renewable energy sources.

How to Achieve Zero Carbon

The amount of carbon that we use is directly related to how we generate our energy. In the UK the aspiration is to 'decarbonise' our grid electricity by introducing renewable technologies into the energy mix. This has had a significant effect already, reducing the carbon emission factor from 0.519KgCO2/kWh down to 0.233KgCO2/kWh. Simply switching from gas to heat pumps to generate our heat and domestic hot water, would reduce this again by half. So, is it a simple case of installing heat pumps in all houses alongside solar pv to offset the electricity used? The chart below breaks down the annual energy demand for a typical new build UK home of 68m2 , firstly with a gas boiler, then with an air source heat pump. The chart indicates that 16 pv panels would be enough to offset the energy demand of the home with an air source heat pump. This, on the face of it, would appear to be easy! There are however, problems…….

Credit: Passivhaus Trust

The Performance Gap

The Performance Gap is a term that describes the difference between modelled energy use and actual energy use in our homes. There is increasing evidence that the energy performance of UK homes in use is actually 40% higher than predicted. This is due mainly to poor construction quality. Including the Performance Gap in our calculations pushes the energy demand of our average home from 4300 kWh/yr to 5400 kWh/yr. To offset this would increase your pv panels from 16 to 20. Introducing stringent construction site standards is imperative to give us a fighting chance of reducing the Performance Gap of our buildings and achieving Net Zero Carbon. In contrast the construction detailing and quality assurance procedures of the Passivhaus Standard ensure that there is little or no Performance Gap between the modelled and actual energy use of the building.

Credit: Passivhaus Trust

Seasonality of Renewables

When it is dark we need light. When it is cold days are shorter and we require more heat. When it is sunny with long days, we require less heat and less light. This is the classic conundrum of renewable energy sources - they are at their highest availability when we do not need them. This is known as Seasonality. In short, our energy demand is at its highest when the availability of renewable energy sources is at its lowest. We can store the energy, but there is significant storage losses incurred when doing this. The result is that ultimately, the effective energy demand of the standard home increases, as does the amount of renewables required to offset it (7700 kWh/yr and 28 pv panels!). This is clearly unrealistic as a viable strategy. The key is to reduce energy demand and close the Performance Gap.

Reducing Demand and Closing the Performance Gap

Emissions associated with heating and cooling a building can be significantly reduced by employing a fabric first design strategy and improving quality of construction. This is the primary focus of the Passivhaus standard, reducing thermal losses by improving the building thermal envelope and aligning this with ventilation heat recovery. Undertaken alongside efficient domestic hot water design and educating occupants in energy efficiency behaviour can drastically reduce the energy demand of the home to a level where energy use in the average 68m2 home with an ASHP could be held as low as 3700 kWh/yr, offset by just 14 pv panels.

Credit: Passivhaus Trust

Comparing Zero Carbon Strategies

The Passivhaus Trust, in their publication Passivhaus: the route to zero carbon?, presents data of net emissions from 5 Zero Carbon scenarios along with the required area of pv panel required to offset regulated energy (heating/ cooling, hot water, lighting + aux elec) and achieve net zero carbon. It demonstrates that a 68m2 Passivhaus fitted with an ASHP and sufficient pv generation capacity to offset energy used has significantly lower net emissions (8kgCO2/m2.yr) than any of the approved building regulations scenarios, in some cases in excess of a 50% improvement. However, none of these scenarios achieve true net zero carbon as unregulated energy use (appliances, etc) and storage losses have not been added when calculating the required renewables to offset. This time, the results show that the proposed move to a notional net zero building (using an ASHP and reducing the TER by 19%) will still have emissions of 3 kgCO2/m2 .year, which would require 32m2 of solar panels to offset. In contrast, the Passivhaus fitted with 22m2 of solar panels lowers emissions to actual zero. Of all the scenarios modelled, this is the only actual zero carbon building.

Credit: Passivhaus Trust

Conclusion

The Passivhaus Trust's study demonstrates that the current Zero Carbon targets won't necessarily realise zero emission buildings. The notional zero carbon buildings that the building regulations demand will in fact generate around 18kgCO2/m2.yr, requiring massive renewables expansion that will not be achievable on every home or flat as there is simply not enough area to accommodate it. Initiating design and build strategies aligned with Passivhaus principles is really our only way to achieve a truly zero carbon building with a manageable level of renewables to offset the energy used. Furthermore, consideration will have to be given to offsite implementation of renewables as it will not be possible on every site. Governments and Developers will have to consider something akin to a Developer's Renewables Contribution scheme to fund offsite renewable generation where onsite capacity cannot be achieved in order to ensure that net zero carbon emissions targets can be met.

In closing we would encourage readers to refer to the detailed report issued by the Passivhaus Trust Passivhaus: the route to zero carbon?

PassivHaus - 10 Design Strategies

Designing to the Passivhaus standard can at times seem quite daunting and intimidating. Understanding the basic principles of the strategy is key, to ensure that you can develop your design to meet the standard without being succumbing to abortive work. This article outlines 10 broad design strategies to follow that will enable you to create a solid foundation from which your design can be developed, increasing your chances of meeting the required Passivhaus Standard.

Designing to the Passivhaus standard can at times seem quite daunting and intimidating. Understanding the basic principles of the strategy is key, to ensure that you can develop your design to meet the standard without being succumbing to abortive work. This article outlines 10 broad design strategies to follow that will enable you to create a solid foundation from which your design can be developed, increasing your chances of meeting the required Passivhaus Standard.

01 Compact Building Massing

Keeping the surface area of your building to a minimum means that you will minimise heat loss, reducing energy consumption associated with space heating. This is known as the Form Factor; the ratio of surface area to internal floor area. The lower the Factor Factor, the more thermally efficient your building will be. The key point here, is to ensure that the thermal envelope is minimised. Simple vernacular forms work best. This does not mean that you have to sacrifice architectural expression however, as this can be articulated via other means out-with the thermal envelope.

02 Location of Unheated Spaces

Co-locate unheated spaces such as stores, bin stores, bike stores. Better yet, separate them from the thermal envelope altogether. This way they do not act as a heat sink, drawing energy from the heated building and complicating your Form Factor. Draw your thermal line and airtightness line around the building at an early stage to manage strategy and detailing, and continue to do so throughout the design process.

03 Optimise solar gain in the Winter through Orientation

In the northern hemisphere, prioritise dual aspect, south facing facades to optimise solar gain during the winter months. Anything beyond +/- 30 degrees is no longer considered a south facing façade by the PassivHaus Planning Package (PHPP). Optimise fenestration and living patterns to take advantage of the path of the sun throughout the day. Avoid overshadowing from neighbouring buildings and vegetation. Consider species of vegetation as well as location. Deciduous trees provide welcome shade in the Summer, whilst allowing solar gain from low angle sun in the Winter.

04 Design Glazing to balance heat gain, heat loss and daylight

Optimise your window design to consider orientation, daylight and summer comfort. Poorly located, excessively large windows are the biggest cause of summer overheating and excessive heat loss in winter months. On East/ West orientations, vertical solar shading devices are best, to the South horizontal solar shading devices should be used to control solar heat gain in the summer months. Minimise heat loss to the north by having smaller windows, whilst taking advantage of solar heat gains via larger windows to the south orientation. Designed in tandem with appropriate solar shading, this strategy will go a long way to minimise the energy requirement of the building.

05 Detailing of Windows

Optimise glazing to frame ratios to increase the thermal performance of the window by reducing the number of mullions and transoms. Triple glazing is almost mandatory in the northern hemisphere to achieve the required U-value standards, so budget accordingly. Windows should be located within the thermal line of the façade to minimise cold bridging and optimise detailing.

06 Natural Ventilation

Try to design dual aspect rooms and homes allowing rooms to benefit from natural cross ventilation. Also, consider night time purge ventilation strategies, particularly in bedroom spaces located on upper storeys. This improves indoor air quality and well-being by optimising user control over their environment.

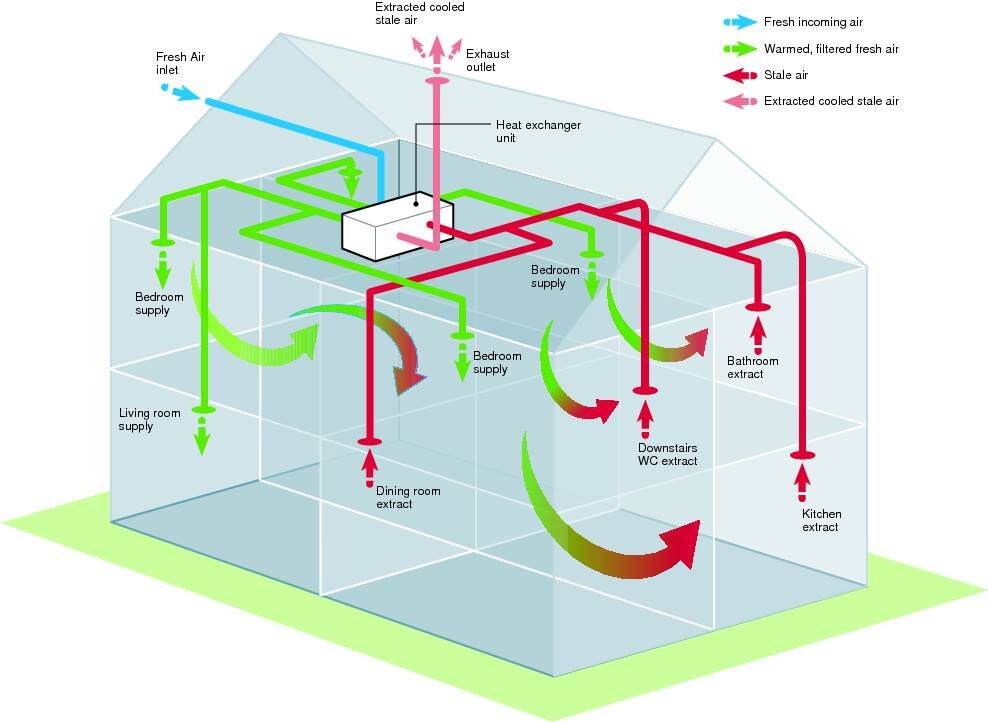

07 Mechanical Ventilation with Heat Recovery (MVHR)

The core plant in any Passivhaus, a suitably designed and installed MVHR system is fundamental to the successful operation of the building.

MVHR units provide background ventilation by extracting moist warm air from kitchens and bathrooms, exchanging the heat to incoming cold fresh air, and then supplying the air to the other rooms in the home. The MVHR unit should be located in a suitably soundproofed room, not more than 2m from the façade. Design of ductwork and distribution is very important to ensure optimal efficiency of the system. Designed correctly and in tandem with a highly insulated fabric, the MVHR system can be sufficient to provide the entire space heating requirement for the home, whilst ensuring a high indoor air quality.

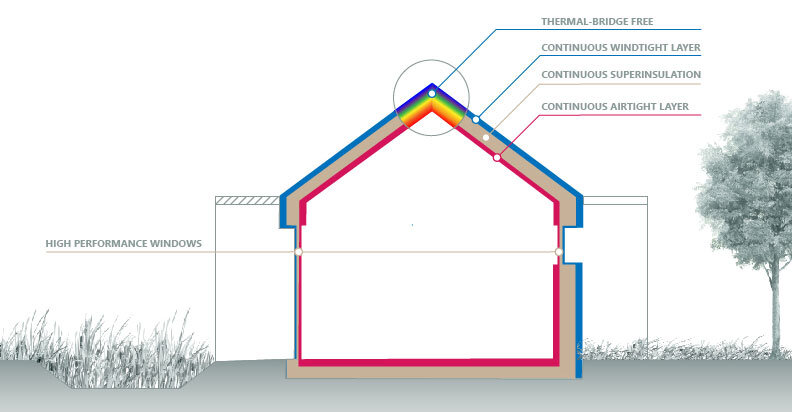

08 Fabric First

The Passivhaus standard requires a highly thermally efficient envelope. It is not prescriptive in how this is met however, allowing designers to consider a multitude of technical options to achieve the desired operational standards. Accepted ranges of thermal performance to aim for are as follows;

Ground Floor - 0.08 to 0.10W/m2k

Walls - 0.13 to 0.15W/m2k

Roofs - 0.10 to 0.12W/m2k

Windows - 0.80 W/m2k

External Doors - 1.0 W/m2k

These are stringent requirements and how you intend to achieve these should be carefully considered against design and budget constraints. Aligned with this strategy is controlling thermal bridging interfaces in the design of the external fabric. Once again, use your 'thermal line' to identify key interfaces that require attention in design to minimise the effects of thermal bridging.

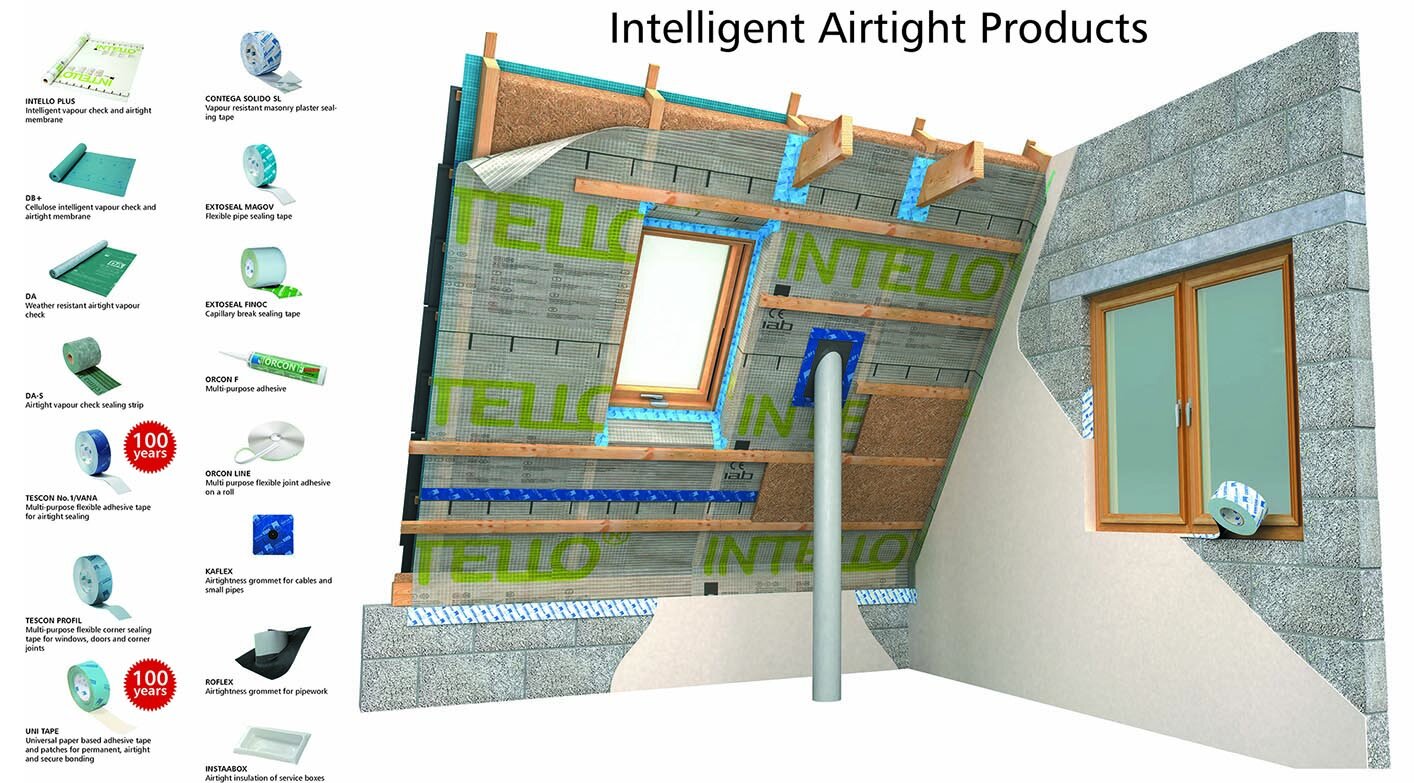

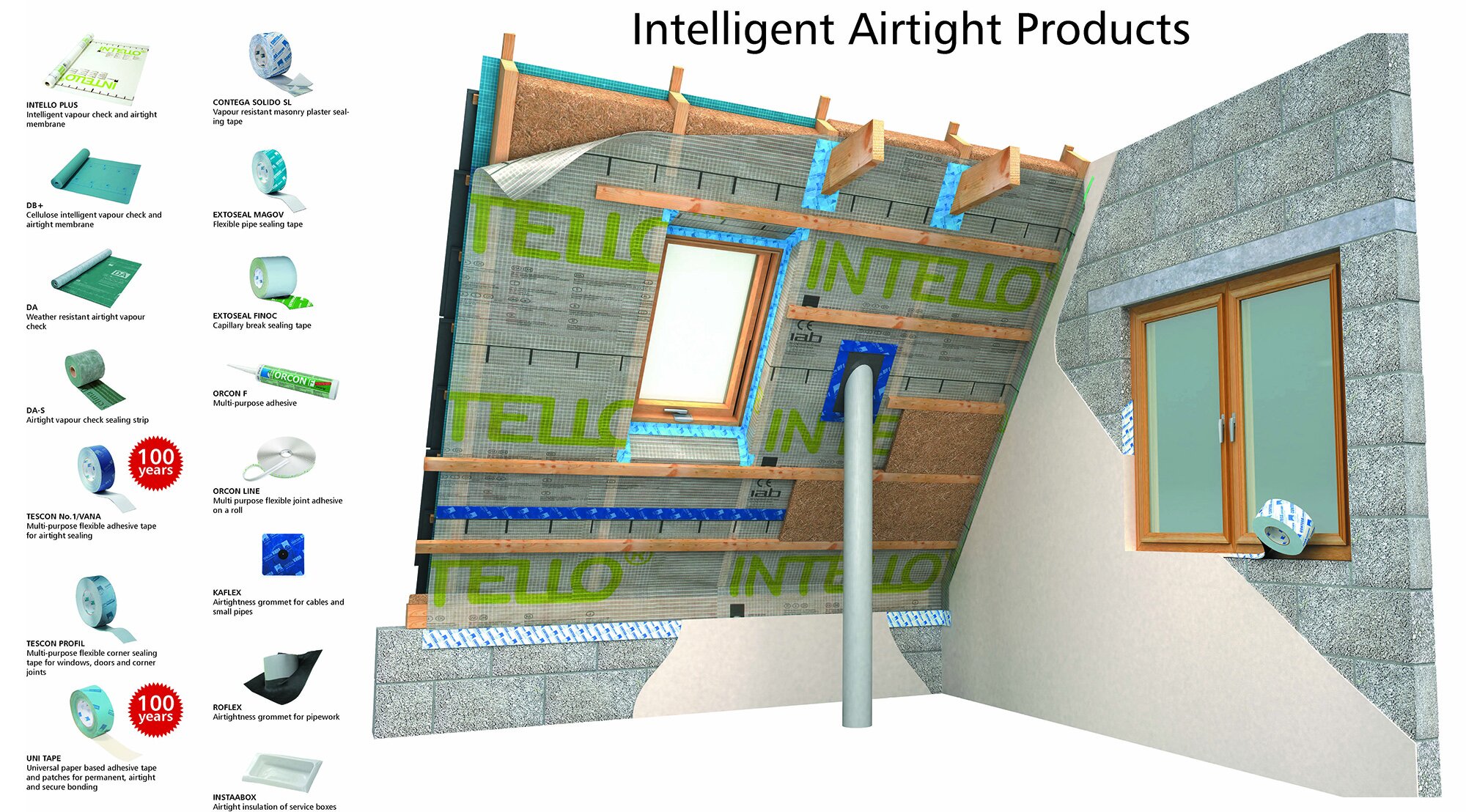

09 Airtightness

Ensuring an airtight building envelope will drive improvements in construction, reduce energy demand caused by air infiltration and draughts, and protect the fabric of your building from premature decay. There are several ways of creating an airtight building, from application of airtight membranes and tapes, to high performance lining boards. The key design strategy is to draw an 'airtight line' on plan and in section around the façade, then focus and manage interface details between different systems and penetrations appropriately. This must be undertaken at an early stage in the design process and followed rigorously through each stage to construction of the building. Achieving an air change rate of 0.6 ACH is required to meet the Passivhaus standard and to ensure optimisation of the MVHR system. This is a rigorous level, when compared to current building regulation requirement of 7.0 ACH.

10 Renewables - getting to net zero carbon

By designing the building to meet the Passivhaus standard, you have taken a significant step towards achieving a net zero carbon building. This is because the building envelope is already so energy efficient that only very low levels of space heating are required. Following a Fabric First approach to achieve the Passivhaus Standard leaves only two more strategic steps to achieve Net Zero Carbon;

Addressing Domestic hot water demand via solar thermal and/ or heat pump.

Addressing electrical demand via implementation of a Photovoltaic array.

Following these 10 simple broad steps will ensure that you stand the best chance of achieving the Passivhaus Standard. You might even get to a Net Zero Carbon home, thus helping in the country's drive towards meeting our 2035 Net Zero Carbon energy targets. At the very least, if you implement some of the strategies, you will have a building or home that is far more energy efficient than the majority of buildings under construction today. All that is required is the implementation of a few simple steps. At Novo, we are happy to assist clients in whatever capacity they require to develop the strategies required to realise an energy efficient building. Please reach out to us by clicking on the button below if you feel we could be of help.

credit: Wain Morehead Architects

PassivHaus Windows Explained

This article is our third in our series discussing Passivhaus 'fabric-first' design principles to improve the energy performance and quality of our buildings. Focusing on Passivhaus Windows, the article highlights the technical requirements of a Passivhaus Window, design detailing and finally discusses the advantages to health and well being experienced in buildings incorporating such systems.

This article is our third in our series discussing Passivhaus 'fabric-first' design principles to improve the energy performance and quality of our buildings. Focusing on Passivhaus Windows, the article highlights the technical requirements of a Passivhaus Window, design detailing and finally discusses the advantages to health and well being experienced in buildings incorporating such systems.

Windows are by necessity a requirement in any building. They have to provide as a minimum daylight and to frame views, but they also play a particularly significant role in the energy performance and thermal comfort of a building. With its emphasis on building comfort, healthy living environments and energy performance, the Passivhaus Standard is particularly demanding when it comes to appropriate specification of glazed elements within your design.

Technical Context

In order to better understand how a Passivhaus Window assists in meeting the standard, it is broken down into various technical performance parameters.

Solar Gains

Designing to optimise solar heat gain in northern Europe is a fundamental principle of successful Passivhaus design. Size and orientation of the window on the site are important in this regard and under the control of the designer. The solar heat gain of the glass (or g-value), a measure of how much heat energy the glass allows to enter the building, is also important. Passivhaus Windows need to have g-value to suit the building location and climate. In northern Europe, this would typically be 0.5 or higher.

Losses

Just as gains are important, so are heat energy losses. The measure of a window's heat loss is its U-value, calculated as an average for the whole window - glass, frame, spacer and installation.

The glass unit in northern European climates is required to have a u-value of 0.7W/m2K or lower to meet Passivhaus Standards. In order to achieve this the glazed unit will often be triple glazed and require an inert gas such as Argon or Krypton to be sealed between the panes. This results in a very heavy window which places particular requirements on the frames and can limit unit size commercially.

The frame is a linear element and as such is given a Psi-value (linear heat transfer coefficient) to determine its thermal performance. The psi-value required of a certified frame must be at least 0.2 W/mK. In order to achieve such values, frame manufacturers often use complex thermally broken frames. Materials used are generally UPVC, Timber or Aluminium.

The second component in determining the psi-value of the frame is the glass spacer. This can be vitally important. In standard double or triple glazed units, often aluminium spacers are used. However, these are highly thermally conductive causing significant heat losses. Passivhaus windows therefore often incorporate plastic or composite spacers to counter this.

Finally, careful interface detailing is required between the window and the wall system to ensure that there are no thermal bridges occurring between the window frame and the wall itself. Consideration of the position of the window relative to the thermal layer of the wall is required to manage this key interface and limit heat transfer through the frame and window reveals. This is vitally important to ensure condensation does not build up promoting mould growth and damage to the fabric of the building.

Once all of the above has been considered, the Passivhaus Planning Package assessment tool (PHPP), will arrive at an Installed U-Value. In northern Europe, this value is set at 0.85W/m2k.

Thermal Comfort Context

But what do all these U-values and psi-values actually mean in the real world?

The thermal performance of a wall is much higher than a window, the window transmitting more heat than the wall. This can cause three main areas of discomfort for occupants;

Draughts. Not caused by wind or poorly sealed windows, but by temperature differential. Warm air in the room contacts the cold window surface and cools down, sinking to the base of the window. This creates the feeling of a draught. Indeed, this is why radiators are often located below windows.

Temperature Asymmetry. If a human experiences a temperature difference of around 4.4 degrees between their head and their feet, then they will feel cold, regardless of the temperature of the room.

Heat loss from our body radiating out towards the colder surface of the window will make us feel cold also.

Passivhaus Windows counter the above through their improved performance requirements over 'standard' window units. A certified Passivhaus Window will only allow a temperature difference of 4.2 degrees cooler than the average internal surface temperature resulting in no draughts, no temperature asymmetry and no excessive heat loss radiating towards the window. The result? Improved thermal comfort.

Health Context

The requirements of the Passivhaus Standard also ensures that the window installation promotes a healthy internal environment. By limiting thermal bridging and condensation, the risk of mould build growth on window surfaces, so often prevalent in 'standard' constructions, is eliminated. The high thermal performance of the window coupled with effective interface design, maintains internal surface temperatures and relative humidity at a level that ensures condensation and mould cannot form. This enhances health and well being for the occupants, but also protects the building fabric, improving durability of components.

credit: mjwarchitects

Consideration of a Passivhaus Window for your building whilst expensive, will give unrivalled thermal comfort, reduce energy bills, protect the building fabric and will more than likely, last longer when compared to conventional double glazed systems. There are many manufacturers now producing Passivhaus compliant systems. If you would like further assistance in determining whether or not such a system is appropriate for your Project, please simply get in touch by clicking on the button below.

PassivHaus Wall Systems

This article is our second in our series discussing Passivhaus 'fabric-first' design principles to improve the energy performance and quality of our buildings. Focusing on the External Wall, the article highlights the general strategies prevalent today with a focus on Timber Frame Structural solutions, the most popular here in the UK.

This article is our second in our series discussing Passivhaus 'fabric-first' design principles to improve the energy performance and quality of our buildings. Focusing on the External Wall, the article highlights the general strategies prevalent today with a focus on Timber Frame Structural solutions, the most popular here in the UK.

Design Principles

The Passivhaus Standard has very stringent requirements with respect to meeting the energy demand of the building when compared to more conventional building standards (Primary Energy Demand of </= 120 kWh/m2.yr and Space Heating Demand </= 15kWh/m2.yr). In order to meet such demands the thermal performance of the building envelope has to be optimised to achieve the following values;

U-value of 0.15 W/m2k or less

Airtightness of 0.6 air changes/ hr @n50 or less

The building envelope therefore must have;

Very high levels of insulation

Airtight building fabric

Windtight building fabric

Thermal bridge free construction

Within the standard there is no limitation on how these values and criteria can be achieved, allowing creativity in design and multiple building systems to be considered. By far the most cost effective system for domestic building in Northern Europe however, is Timber Frame Construction. Within this 'system', the parts themselves are interchangeable, providing the opportunity to choose from a vast array of different elements and components to achieve higher levels of performance and economy. Such systems are light weight, easy and quick to transport and construct and are robust. Whilst there are many derivatives of timber frame construction, all are characterised by an internal zone for running services and applied internal wall finishes and an external cladding zone capable of supporting a wide variety of external cladding systems to meet aesthetic and regional requirements.

Broadly speaking, timber frame construction is split into two approaches, open panel construction and closed panel construction. Open Panel construction relies upon simple open stud framework being erected, then insulated and clad on site. Closed panel construction optimises the advantages of offsite manufacture, forming modular panels in a factory complete with an enclosed structure, insulation and protective sheathing layers to the internal and external face of the panel. Open Panel is often slightly cheaper, but Closed Panel construction offers the benefits of improved build quality.

Open Panel Construction

In order to meet the stringent thermal requirements of the Passivhaus Standard, open panel systems will typically be constructed from 184mm deep timber studs, supplemented by additional thermal layers of insulation placed externally or internally to alleviate thermal bridging through the timber studs impacting upon the overall U-value of the assembly. This allows a wide use of insulation material to be considered, dependent upon cost, performance and environmental strategy. A typical assembly comprises the following;

External cladding zone

Windtight, breather membrane

OSB Sheathing board

184mm timber studs at 600mm centres

Insulation infill

Airtight and vapour control layer (membrane or board)

Supplementary thermal insulation layer

Service void

Internal wall finish

Advantages

Low cost

Leveraging common construction skills

Versatile

Medium speed of construction

Flexibility in design

Disadvantages

Highly dependent on site supervision

Required build quality hard to achieve

Slow erection times when compared to other methods

Closed Panel Construction

Optimising the advantages of offsite manufacturing techniques, closed panel construction is becoming increasingly popular. Broadly speaking there are three types of system used.

Closed Panel System 01

Essentially an offsite version of an open panel system, many suppliers now offer what can be considered an entry level closed panel system. Typically the panel is supplied with both external and internal sheathing boards fitted with the panel being fully insulated. In some cases external cladding rails and finishes can also be applied subject to logistical constraints. These systems can also take advantage of manufactured I-Joists replacing the traditional 184mm stud. These can provide a deeper wall, increasing insulation and reducing thermal bridging through the stud.

Closed Panel System 02

Another way of increasing the levels of insulation beyond a standard 184mm stud whilst also minimising thermal bridging through the structural timber elements of the wall is via a split-stud or twin stud wall. In this construction, two lines of studs 90mm wide are placed tied together at intermediate heights of 600mm vertically. This allows any depth of wall to be constructed to achieve the required thermal performance of the construction. Other advantages include optimising the integration of intermediate floors and roofs to minimise thermal bridging and improve the thermal performance of the entire structure. Beyond the structural layer, the system shares the same characteristics of other timber frame systems.

Credit: MBC Timber Frame

Closed Panel System 03

The final closed panel system is a Structural insulated Panels Systems or SIPS for short. SIPS panels comprise high density EPS or Foam insulation and timber studs sandwiched between two layers of sheathing board, typically OSB board. The result is a composite panel of high strength and thermal performance capable of large spans. These panels are able to be used as walls, roofs and even floor cassettes. Manufactured under factory conditions, the panels are quick and easy to transport and erect on site, achieving wind and watertight status very quickly. They are best suited to modularised simple forms, their efficiencies quickly compromised when more complicated forms are desired.

Advantages

Speed of construction on site is high

Whole façade option

Improved build quality

Modular build

Building performance generally improved

Disadvantages

Can be costly

Specialist structural input required

Supplier choice scarce

Can be inflexible due to modular build strategy

Can require specialist erection team

In June of 2019 the UK became the first major economy in the world to commit to producing net zero greenhouse gas emissions by 2050. Enshrined in Law this means that all industries, including construction, must operate at net zero carbon by 2050. Indeed in Scotland, the devolved administration has committed to a date of 2045. Some cities such as Edinburgh and London, have even more aggressive targets of 2030 in mind. To meet these targets the built environment, in particular our homes, will have a continuing requirement to meet increasing energy efficiency targets. The net result of this will be a continued drive towards off site manufacturing techniques such as the ones described in this article, to ensure post occupancy energy performance targets are met.

The above systems are all capable of providing an energy efficient façade and are becoming increasingly popular in the UK, in particular in the Self-Build Home sector. Choice is available. All are capable of delivering a building performing to the Passivhaus Standard. Choice will be dependent upon a combination of factors including cost, speed of construction, technical expertise of your team and complexity of design.

If you have found the above article useful and would like to understand more about the Passivhaus Standard, we would encourage you to read the other articles in our blog available at www.novo-design.co.uk/blog. Alternatively you can join our mailing list below.

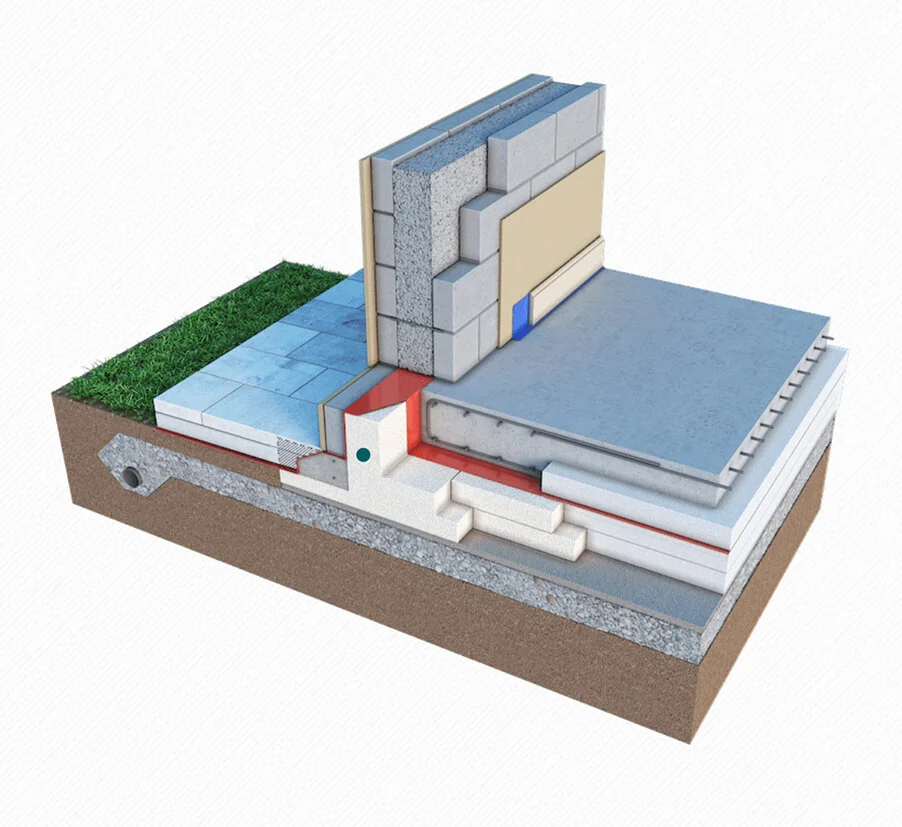

PassivHaus Foundation Systems and Details

This article is the first in a series discussing how integrating Passivhaus ‘fabric first’ principles vastly improves the energy performance and quality of our buildings. Focusing on foundation design, the article highlights the three broad design strategies employed to optimise the thermal performance of the building.

This article is the first in a series discussing how integrating Passivhaus ‘fabric first’ principles vastly improves the energy performance and quality of our buildings. Focusing on foundation design, the article highlights the three broad design strategies employed to optimise the thermal performance of the building.

Context

As energy performance goals begin to rise, the potential for heat loss through the base of buildings has come in to sharp focus. Concrete basement walls, stem walls and slab edges can no longer be left exposed to winter air or frozen soil near the surface compounding thermal bridging, causing significant condensation and mould growth at key interfaces. Infiltration of cold air up through suspended floors has also been identified as a problem.

In answering such design challenges, designers proposed insulating the building perimeter down to a sufficient depth that the temperature differential between the soil and the foundation system was no longer considered a problem. Alternatively, insulation could be extended out horizontally from the building perimeter just below grade level. This protects the soil mass directly under the building perimeter from heat loss to the surface. Combination of these techniques is still in use today.

To meet Passivhaus standards in harsh climates such as those experienced in central and northern Europe, it is necessary to completely isolate the foundation system from thermal contact with the soil. In addition, perimeter drainage systems are required to reduce fluid pressure against such foundation systems as well as protecting the integrity of embedded barriers and materials within the system from soil that would otherwise be saturated with water.

Design Strategy

The core design challenge is to maintain thermal isolation between the structure and grade whilst transferring loads from the building via walls and columns to the foundation. The most straight forward approach is to surround the entire foundation in insulating material. This approach allows the mass of the foundation to hold the building down assisting detailing with all connections to the slab within the thermal envelope. It also has the added benefit of the slab acting as a thermal store for the building, enabling internal temperatures to be regulated more easily. Design challenges present themselves at interfaces with door openings and external landscaping, but these can be easily resolved via simple flashings and appropriate detailing to protect the integrity of the exposed insulation at the slab edge. There are numerous systems like this on the market presently from suppliers such as Kore Insulation and Isoquick.

Strategy 01

Insulated Raft Slab Foundation

A second strategy available for consideration is more of a hybrid of traditional strip foundations and the insulated slab outlined above. In this strategy, a conventional strip foundation, common in the UK, is installed with insulation extending down both sides of the sleeper wall (whether cast concrete or concrete block on a footing). This does not eliminate thermal conductivity through the base of the footing, but it does reduce thermal losses at the key interface with the ground floor. This option is popular as it is familiar with traditional foundation practices and can reduce concrete quantities. However, interfaces with other systems such as membranes and fixings are more complicated and difficult to control.

Strategy 02

Insulated Strip Foundation + Ground Slab

Where large amounts of concrete are considered undesirable or not possible for logistical or financial reasons, suspended timber ground floors with a ventilated air space below to control moisture from the ground are still possible to meet Passivhaus standards. With similar design challenges presented by the hybrid solution outlined above, care should also be given to maintaining integrity of the membrane and perimeter insulation at the interface with the required ventilation slots to promote airflow to the subfloor. This adds construction complexity, but if executed well, can provide a robust lightweight ground floor construction that performs well. Care should also be taken to ensure infiltration of cold air from the subfloor is eradicated through the inclusion of an airtight layer of appropriate board or membrane.

Strategy 03

Suspended Timber Floor

The three broad strategies outlined above if executed correctly, will provide a sound thermal bridge free foundation from which to realise your Passivhaus building. It is important to understand that the foundation is the first area where the thermal integrity and, by extension energy use, of the building is challenged. It is vitally important that clear dialogue of the building's energy strategy is communicated to the design team, in particular, the Structural Engineer and Architect, to ensure that all the hard work undertaken in the design and performance of the Superstructure is not lost at the key interface with the ground.

If you have found the above article useful and would like to understand more about the Passivhaus Standard, we would encourage you to read the other articles in our blog available at www.novo-design.co.uk/blog. Alternatively you can join our mailing list below.

PassivHaus - 5 FAQs answered

This article focuses on concise responses to 5 frequently asked questions that I get asked about the Passive House Standard.

Ostro house, Paper Igloo Ltd

What is passive about Passive House?

Passivhaus is a building design strategy targeted at achieving specific stringent energy performance standards. The result is a Passive House that requires very little energy to maintain a constant pleasant internal environment within which to live. In this sense, such dwellings and commercial buildings can be considered 'passive' as they need very little active heating or cooling to remain habitable by virtue of their design. This is predominantly achieved via the implementation of intelligent design and execution on site, high insulation levels, high performance windows and doors and efficient heat recovery systems. A good analogy is a cave, cool in summer and warm in winter.

Why build airtight? Don't buildings need to 'breathe'?

Conventional building methods are susceptible to high levels of air infiltration, perceived in the worst cases as draughts. Whilst this provides 'ventilation' it is uncontrolled, uncomfortable, leading to high heat energy loads and poor air quality indoors. This often necessitates the opening of windows regularly for extended periods to 'get some fresh air'. An airtight building envelope gives the occupant ultimate control of the ventilation of the building, eliminating draughts and reducing the heat load on the building significantly. It also protects the building structure, preventing condensation build up and resultant mould growth. The mechanical ventilation system in an airtight building can deliver clean fresh air to rooms where it is needed and remove moisture laden air where it is not needed. It can also recover waste heat from this air and reuse it within the building, reducing heat load demand further.

Can you open the windows in a Passive House?

One word. Yes! In conventional buildings, occupants often open windows to get 'fresh air' and remove stale indoor air. In a Passive House, airtightness and the mechanical ventilation system ensure that indoor air quality is maintained continuously, regardless of the temperature outside. The result is that occupants in a Passive House are less likely to want to open windows. Nevertheless, they can if they wish. An added benefit, is that the filters installed in the mechanical ventilation system remove pollutants, VOCs and pollen from the incoming air, improving the health of occupants.

What is so special about Passive House windows?

Conventional buildings today, tend to have double glazed windows with one or two seals. This often leads to large temperature differentials at the window, cold draughty frames and condensation in poorly ventilated buildings. In cool temperate climates, such as the UK, Passive House windows tend to be triple glazed, with thermally broken frames and often with three seals. Such high quality windows let more of the sun's heat energy in (solar gain) than is let out in the winter months. The temperature differential at the window between indoors and outdoors is far less, resulting in no condensation or feelings of draughts. Orientation of the windows must be optimised to take advantage of these solar gains and protection measures considered to avoid overheating in summer. Even in the UK, a poorly designed Passive House can lead to overheating in Summer months if protection from solar gain is not considered during this time.

How comfortable are Passive Houses in Summer?

Due to their high thermal mass and high levels of insulation, Passive Houses protect their occupants from hot summer conditions by keeping outdoor heat from entering the building. The high thermal mass of such buildings acts like a cave, storing heat slowly during the day and dissipating it at night. As alluded to above, careful design of window orientation and solar shading devices is often implemented to reduce overheating caused by solar gain. Indeed, the Passive House standard requires that the indoor temperature of the building does not exceed 25 deg C for more than 10% of the year. In the summer months the ventilation system often is switched to a summer-bypass which disengages the heat recovery option, enabling further control of the indoor temperatures. In essence, when optimised, the design strategy supports a comfortable summer environment indoors.

In closing the Passivhaus Standard is a simple uncomplicated design strategy that ensures a well built, low energy home that is comfortable and healthy to live in. There are many more questions that we get asked, so if you have any please do get in touch and we would be happy to answer them.

If you have found the above article useful and would like to understand more about the Passivhaus Standard, we would encourage you to read the other articles in our blog available at www.novo-design.co.uk/blog. Alternatively you can join our mailing list below.

MVHR explained

This article focuses on one of the most important mechanical service systems in a Passivhaus building, the Mechanical Ventilation with Heat Recovery (MVHR) System. In designing to the Passivhaus standard, it is important to understand how MVHR works, what it requires, what it does and also what it does not do. MVHR executed correctly, is key to delivering the benefits that the Passivhaus Standard promises; a comfortable, healthy, energy efficient building.

What is MVHR?

Simply speaking an MVHR system does two things. It provides Mechanical Ventilation and Recovers Heat. Fresh air is supplied to the habitable rooms of the building via a network of ducts and stale air is extracted by a separate system of fans and ducts. The supply and extract systems are separate. Heat recovery uses a heat exchanger to remove heat from warm air and transfer it to cold air. Warm air is extracted from rooms, typically the kitchen and bathrooms, then passed over the heat exchanger where the heat is removed, before being expelled to outside. The harvested heat energy is then transferred to the cold supply air by the heat exchanger and delivered to the habitable rooms such as the living room and bedrooms. Thus, expensive heat energy is retained within the building leading to high level of energy efficiency. Conventional mechanical ventilation systems, such as the one in your bathroom or kitchen, simply remove the warm air and dump it outside, wasting valuable heat.

An MVHR system is optimised when it is balanced; the amount of air coming into the building is equal to that leaving the building. This gives control over air movement maximising the amount of heat that can be recovered and reused. To achieve this the building must be Airtight. Air leakage and infiltration must be minimised. In this way building standards are far higher in a Passivhaus Building. Refer to our article on Airtightness for more detailed information. The greater control achieved by MVHR and Airtightness enables a more comfortable internal environment to be achieved and maintained for the end user.

What is required in an MVHR system?

Every MVHR system typically has the following key features;

Two grilles on the external façade, suitable spaced apart. One for fresh supply air and one for stale exhaust air.

Coupled to these grilles are two lengths of duct connected to the main MVHR unit. It is important to keep these as short as possible as they are both full of cold air. As such they should be suitable insulated with vapour permeable insulation to prevent condensation forming. The ducts also need to be airtight as they interface with the thermal envelope and airtight layer of the building.

MVHR unit itself. Inside the unit the fresh incoming air passes through a filter to remove debris and pollutants before passing over the counterflow heat exchanger, where heat harvested from the exhaust air is transferred. Both the supply and extract air streams have small in line fans to maintain air movement.

On the other side of the unit are two further ducts. One goes to all habitable rooms in the building. This is the duct supplying warm fresh air to the building. Often a small in line heating coil can be installed to assist with bringing the air up to temperature. The other 'extract' duct brings stale warm air 'back' to the unit from rooms where air is extracted. These rooms are typically kitchens, utility rooms and bathrooms. This air passes through a filter before entering the unit to remove airborne dust and debris before entering the heat exchanger.

Both of these ducts will have silencers on them to remove any noise associated with the continuously running fans. It is worth noting that the Passivhaus Standard demands that such systems run 'almost silently'.

If a duct passes between different rooms, it is good practice to fit a cross-talk silencer to ensure that noise is not transferred between rooms through the duct.

Whilst the system is very simple, it is recommended to have a qualified person design and coordinate the system for you. The system must be balanced and ducts sized accordingly to operate optimally. Equally, there is a significant interface with other systems within the building that requires detailed organisation. It is essential that the MVHR system is designed and integrated at an early stage in the design process.

What MVHR Does Not Do

It is important to note a number of things that MVHR does not do. Firstly it is not air conditioning. It does not provide cooling, although this can be added to the system if required. Secondly, it does not recirculate air, it always supplies fresh filtered air. Stale air is always expelled from the building following removal of its heat energy. Thirdly, it does not supply 'unhealthy' outdoor air as all air is filtered. Lastly, it does not extract air directly from kitchen cooker hoods. It is always recommended to install a recirculation cooker hood with grease filter that is not connected to the MVHR system. This protects the MVHR system from grease laden air entering the heat exchanger and blocking it.

What MVHR Does Do

An optimised MVHR system will do the following;

Provide controlled constant fresh air to the building improving health and well being.

Filter incoming air from pollutants, particulates and pollen, improving health and well being.

Reduces energy bills by removing waste heat from stale air and reusing it to warm incoming fresh air, reducing the heat load on the building.

Be highly energy efficient, using less energy to power the fans than it saves in harvesting waste heat energy.

Removes moisture and excess humidity from warm stale air, preventing condensation and mould, improving health and protecting the fabric of the building.

Removes indoor pollutants from the air reducing CO2, VOCs improving health, well being and improving sleep.

Installing MVHR in your home will provide you with thermal comfort, energy efficiency and control over the quality of air you breathe. It ensures that healthy comfortable ventilation is provided consistently to the rooms where it is required. It also protects the integrity of your building from the damaging effects of moisture laden air and condensation. Lastly, it provides a context for control of your internal environment. You can open windows when you want, but more importantly, you can keep them closed and still enjoy adequate ventilation and thermal comfort.

If you have found the above article useful and would like to understand more about the Passivhaus Standard, MVHR or more, we would encourage you to read the other articles in our blog available at www.novo-design.co.uk/blog. Alternatively you can join our mailing list below.

What is BIM?

Building Information Modelling, or BIM for short, is rapidly gaining traction in the construction industry, but what exactly is it? This article provides a brief explanation of BIM for our clients, outlining how Novo is integrating the processes and tools into our workflow to provide our clients with an improved optimised service and experience.

BIM is simply a process for creating and managing information on your construction project across the project life cycle, from design inception, to construction, to management of the building in-use. One of the key outputs of the process is the Building Information Model, a digital entity describing every aspect of the built asset. The model is not simply a 3D computer generated model, but rather should be considered as a 5D coordinated repository of information assembled collaboratively, updated and coordinated by all members of the team throughout the project life cycle.

At Novo we have been using BIM software for nearly a decade. However, it is only in the last 2 years that we have really started to ramp up integration with other members of the design team. BIM enables us to bring together all of the information about every component of a building, in one place. This makes it possible for anyone to access that information for any purpose, e.g. to integrate different aspects of the design more effectively. In this way, the risk of mistakes or discrepancies is reduced, and abortive costs minimised.

BIM data can be used to illustrate the entire building life-cycle, from inception and design to demolition and materials reuse. Spaces, systems, products and sequences can be shown in relative scale to each other and, in turn, relative to the entire project. And by signalling conflict detection BIM prevents errors creeping in at the various stages of development/ construction. We also use it for thermal modelling of the building, to inform and optimise our design solutions to provide a low energy use solution.

Our two principle tools that we utilise in our BIM workflow are Archicad and NBS Chorus, our computer aided design software and specification software. These tools integrate seamlessly with each other to create a digital model rich in data and interoperability for the design team to utilise. The model enables us to produce a comprehensive set of coordinated information in real time. It assists us with design explanation, detailing, thermal modelling, coordination, cost control and construction sequencing. At project handover it provides the client with a detailed digital record of all aspects of the building allowing them to manage and maintain the asset appropriately.

Advantages for the Client

Improved design decision making through 3d modelling

Reduced costs by managing and minimising errors in the digital environment first

Reduced in-use energy costs through innovative thermal modelling

Cost certainty at each stage of the design process

Better management of the building during occupancy

To date, due to cost of implementation, BIM has generally been reserved for larger projects. In our Studio, we are certainly convinced that the early implementation of BIM into our workflow on smaller projects has greatly improved the quality of our service for our Clients. In some ways this is innovative on such a small scale, however we are excited by the possibilities that it promises. Moving forward it is our intention to rollout live interactive cost modelling to provide increased cost certainty on projects. With each component having an identifiable cost, quantities and cost management will be greatly improved for our clients. Further development will also look at closing the gap between design model and site construction and assembly, exploring the possibilities of off-site manufacture. In this way we look forward to having a greater influence on control of quality and performance of the final built asset.

All of our new projects will be integrating BIM protocols. If you feel that your project could benefit from this innovative tool we would love to assist in any way that we can, just contact us below.

airtight construction explained

The Passivhaus Standard requires airtight construction to perform to its potential. What does this mean? Essentially it means a draught-free building envelope, protecting all of that expensive heated air from inside your home leaking to outside.

Airtight construction, or airtightness, quite simply means that there are no unintended gaps in the building envelope that allow air to leak in or out of the building. This means there are no cold draughts coming in through the building envelope. It also means there are no unintended gaps that allow moisture laden air from inside the building to leak into the materials of the building envelope.

Unintended gaps are created through poor detailed design or execution of key interface details between different elements of construction of the thermal envelope. To achieve airtight construction, a continuous uninterrupted air barrier line must be identified and executed in the thermal fabric of the building. It should be possible for your designer and contractor to readily identify and execute this line to form a closed thermal airtight loop to your building.

The second important principle is to minimise, control and execute penetrations through this barrier effectively. All necessary penetrations should be minimised and executed with appropriate detailing at design stage and executed comprehensively on site, to ensure that they are not the cause of unintended air leakage.

Your airtight layer can be formed from many different materials. Popular materials include wet plaster on masonry construction, reinforced concrete, Oriented Strand Board (OSB) of a suitable thickness, and specifically designed airtight membranes. In addition to the materials that make up the building fabric, windows, doors, curtain wall systems and roof lights need to be airtight components. Interfaces betweem different materials and components are executed with appropriate air sealing tapes.

What Airtight Construction is Not

A common misnomer is that airtight construction compromises effective ventilation of a building. This is not the case. Rather, airtight construction actively controls and betters effective ventilation of the building. In a Passivhaus, the ventilation air entering the building is controlled via a mechanical ventilation system and opening windows or vents. Unlike 'standard' non-airtight construction that relies on indiscriminate infiltration and air leakage to meet ventilation needs of the occupants, airtight construction controls air movement delivering better quality air at a time and temperature that is desired by the end user.

Why Focus on Airtight Construction?

First and foremost, building airtight will ensure protection and longevity of your building envelope. It prevents moisture laden air from inside the building from occupants, cooking, washing, etc from penetrating the expensive parts of the building envelope where it can condense and cause damage to the building structure. A 1mm gap in your airtight layer will quite happily transmit 360g of water per day into your building envelope, where it may condense and cause damp, mould, etc.

Secondly, airtight construction is required to optimise energy efficiency. Simply speaking it prevents expensive heat from escaping. Alongside insulation, airtightness prevents heat loss through the fabric of a Passivhaus. The air barrier also prevents efficiency losses in the insulation caused by moisture build up.

Thirdly, airtight construction is draught free, very important in Scotland! Regardless if internal temperature, draughts cause a perceived temperature differential to occupants, causing them to increase heating temperature to counteract this feeling. This is costly due to increased energy use.

Lastly, in a Passivhaus, airtight construction is required to optimise the operation of the MVHR (Mechanical Ventilation with Heat Recovery) unit, the principle source of ventilation and heating in the dwelling. Without airtight construction, heat energy in the air is lost through leakage and recovery of the heat from the air is therefore lost, leading to inefficiencies in the system.

Airtight construction is quite simple in concept. It does not have to be complicated. In simple terms it is about employing a well thought through strategy to ensure a draught free dwelling that will protect the building fabric from damage caused by moisture laden air. It is about giving the occupants control over the quality of air in their internal environment, whilst optimising energy efficiency. You can still open windows and doors as desired!

All of these aspects make airtight construction essential for any high-performance building, and indispensable for the Passivhaus Standard. If the above article is of interest and you would like to know more, or if you feel that we could assist you with your new home, we would be happy to help. Just click on the button below to contact us.

What is a Passivhaus Designer?

As a Certified Passivhaus Designer, I am often asked what exactly they do, what can they bring to your Project?

The international Passivhaus Standard is a clearly defined and rigorous standard for energy efficiency, comfort and quality assurance of buildings. Designing a building to achieve the standard requires detailed knowledge and a rigorous methodical approach to design and documentation. Employing a Certified Passivhaus Designer ensures that your Building stands the best chance of performing to this rigorous standard.

A Certified Passivhaus Designer, regardless of their prior qualification, works across disciplines on a Passivhaus project. Their role integrates architecture, structure, building services, building science, energy modelling and construction detailing. They will at times both support and challenge the other designers on a Passivhaus Project.

The individual also does not need to be completely independent. They can also be the architect, structural engineer, building services engineer, or another consultant on the team; fulfilling two roles has many advantages, bringing consistent detailed knowledge and a rigorous methodical approach to the design of your home to meet the international Passive House Standard. At Novo, we regularly work with other design teams in an advisory capacity.

A Passivhaus Designer is trained in the fundamentals of Passivhaus design. This includes the ‘hard requirements’ – 10W/m2, 15kWh/m2.a heating/cooling demand, 120kWh/m2.a Primary Energy, 0.6ach, etc, as well as the ‘soft requirements’ (comfort and hygiene criteria) and the functional definition of a Passivhaus building. Check out our Blog Post What is Passivhaus? for more information.

With a good knowledge of the fundamentals, a Passivhaus Designer is able to communicate the benefits of Passivhaus to a client, as well as the advantages and features. They are also able to communicate the impact on the design process and design outcomes to other designers on your Project team.

A key to Passivhaus design is identifying the aspects of heat energy balance that the building design can influence; where heat is gained and lost due to the design of a building. Key strategic design strategies include building shape / mass, glazing, shading, insulation / thermal bridging, airtightness and ventilation. These are important for both energy efficiency and comfort.

Quality control is also key to Passivhaus design. The design of the thermal envelope needs to be rigorous to ensure that insulation and the airtight barrier is continuous and effective when built. U-values need to be robust and reliable. Thermal bridges need to be eliminated by design or thermally modelled. Detail design is key at this stage as well as monitoring execution of these details on site. All areas where the Passivhaus Designer can assist your team.

A Passivhaus Designer is also trained in space planning for Passivhaus. How internal rooms and spaces relate to solar heat gains, internal heat gains, ventilation and building services all need consideration as early as possible. Space planning can have a considerable impact on the ease and cost effectiveness of achieving the Passivhaus Standard.

The final aspect of Passivhaus design is the building certification process. A Passivhaus Designer can guide a client and team through the process, but cannot certify a Passivhaus building. Only an independent Passivhaus Building Certifier can certify that a building meets the international Passivhaus Standard requirements. Of course, you do not have to have your building Certified, simply following the principles of Passivhaus will ensure that your home performs well above that of 'standard' homes.

Can it be Built and will it be Airtight?

Most buildings suffer from a performance gap between the design predictions and the actual building performance. Passivhaus effectively eliminates the performance gap. Part of this success is due to the care and attention to construction detailing. This ensures that what is designed can and will be built as intended and that it meets the requirements of the Passivhaus Standard.

Many aspects of a design are fixed during the design stage and ideally never get changed during construction. Regardless of design, several critical aspects are still dependent on good construction quality, though. These include;

Glazing – weatherproof and airtight installation without thermal bridging is needed.

Airtightness – a continuous, unbroken, air barrier is needed.

Insulation – continuous installation without thermal bridging or gaps is needed.

Ventilation – correct, high-quality installation and commissioning is needed.

Too often architects and designers draw details that aren’t easy to build. This can result in compromised quality and performance when constructed (as well as headaches for the builder), or on site changes being necessary. Neither of these outcomes is ideal for any project and part of a Passivhaus Designer’s role is to help avoid them. A Passivhaus Designer will review all construction details with an eye for how the continuity and integrity of the building envelope will be delivered. They will be looking at the weather proofing, the insulation, the air barrier and the buildability of the detail.

Airtightness often needs additional care and attention as the Passivhaus requirement of 0.6ach is still perceived as a challenge by many in the industry. It is, therefore, critical, that the design, detailing, and documentation makes it as simple, straightforward and clear as possible to understand the airtightness strategy and to achieve it on site.

A Passivhaus Designer’s role with regards to airtightness may extend to providing toolbox talks and installer briefings on site. Explaining the purpose and methodology to achieve an airtight building envelope often helps to raise aspirations on site. It also reinforces the important contribution each trade can make to the quality and performance of a building.

Site support is also very important, visiting the site and observing construction progress is a critical role of the Passivhaus Designer. With their specialist training and understanding of what details matter for Passivhaus, a Passivhaus Designer may spot something critical that an architect or clerk of works doesn’t. They should also be able to assist in resolving any issues that arise to ensure your building has the best chance of performing to the standard.

Building Services, even for Architects

Integrated design is vital for successful Passivhaus design. And building services are an important part of any building design. A Passivhaus Designer, even if they are an architect, is trained in the design of building services for Passivhaus. Building services include ventilation, heating, hot water, lighting, and appliances.

Ventilation is the most important of these and given the most detailed consideration. For ventilation and heating, the starting point is the comfort (and hygiene) requirements of the international Passivhaus Standard. Ventilation is needed to provide fresh air and to remove odours, pollutants (CO2, VOCs), water vapour (humidity control for comfort and to avoid mould etc) and excess heat (summer cooling). Additionally in Passivhaus buildings, the ventilation system preheats incoming fresh air (via the heat exchanger) to avoid cold draughts and filters out dust and pollen. In some but not all Passivhaus designs, the ventilation also delivers the heating.

A Passivhaus Designer is trained in designing the ventilation system and the related duct sizing and layout. This is an important part of an integrated design and a very useful skill for an architect to have if they are also a Passivhaus Designer. The ventilation system design is ideally developed at the same time as the architectural design. This way spaces for the equipment and ducting can be intentionally allowed for rather than shoehorned in later. It also means both energy and cost effective locations for equipment can form part of the design.

Early design decisions relating to the building services can have a big impact on the cost-effectiveness of a Passivhaus design. A Passivhaus Designer can help ensure intelligent design decisions are made to keep costs in check.

Hot water makes up a noticeable part of energy consumption in a Passivhaus building. User choice and patterns of use can have a huge impact on this and are out of a designer’s control. Heat loss from the distribution of hot water is less dependent on actual use patterns and can, therefore, be minimised through Passivhaus design. This is important to reduce energy consumption.

Artificial lighting also makes up a noticeable part of energy consumption in a Passivhaus building. The first approach a Passivhaus Designer will take is to minimise the need for artificial lighting by good daylight design. After that, it comes down to efficient layouts, sensible light levels and selection of energy efficient fittings.

A Passivhaus Designer brings an integrated cross-discipline design approach.

Passivhaus design is optimised integrated design.

A Passivhaus Designer is trained and knowledgeable in the fundamentals of the international Passivhaus Standard, the building science of Passivhaus, the construction of Passivhaus, and building services for Passivhaus. They bring all these aspects of the design together across multiple disciplines to ensure the success of your project.

A Passivhaus Designer can also be the architect or engineer on a project, or they can be independent. In either case, it is best that they are an integral part of the design team and process.

It can be beneficial to a project if the architect and engineers are trained as Passivhaus Designers, even if they don’t carry out the role of the Passivhaus Designer on the project. The knowledge and the mindset of a Passivhaus Designer brings considerable benefit to their way of designing within their own discipline.

As Certified Passivhaus Designers, Novo Design Studios is well placed to advise you on any questions that you may have. We not only love incorporating Passivhaus principles into our own work, but love helping other design teams reach improved energy efficiency standards in their Projects. If you think we could work together on your next project, then please contact us and we will be in touch to discuss how we might work together.